#014 DIY Spot Welder

Contrasting with other articles on my website, this article has a more instructive tone.

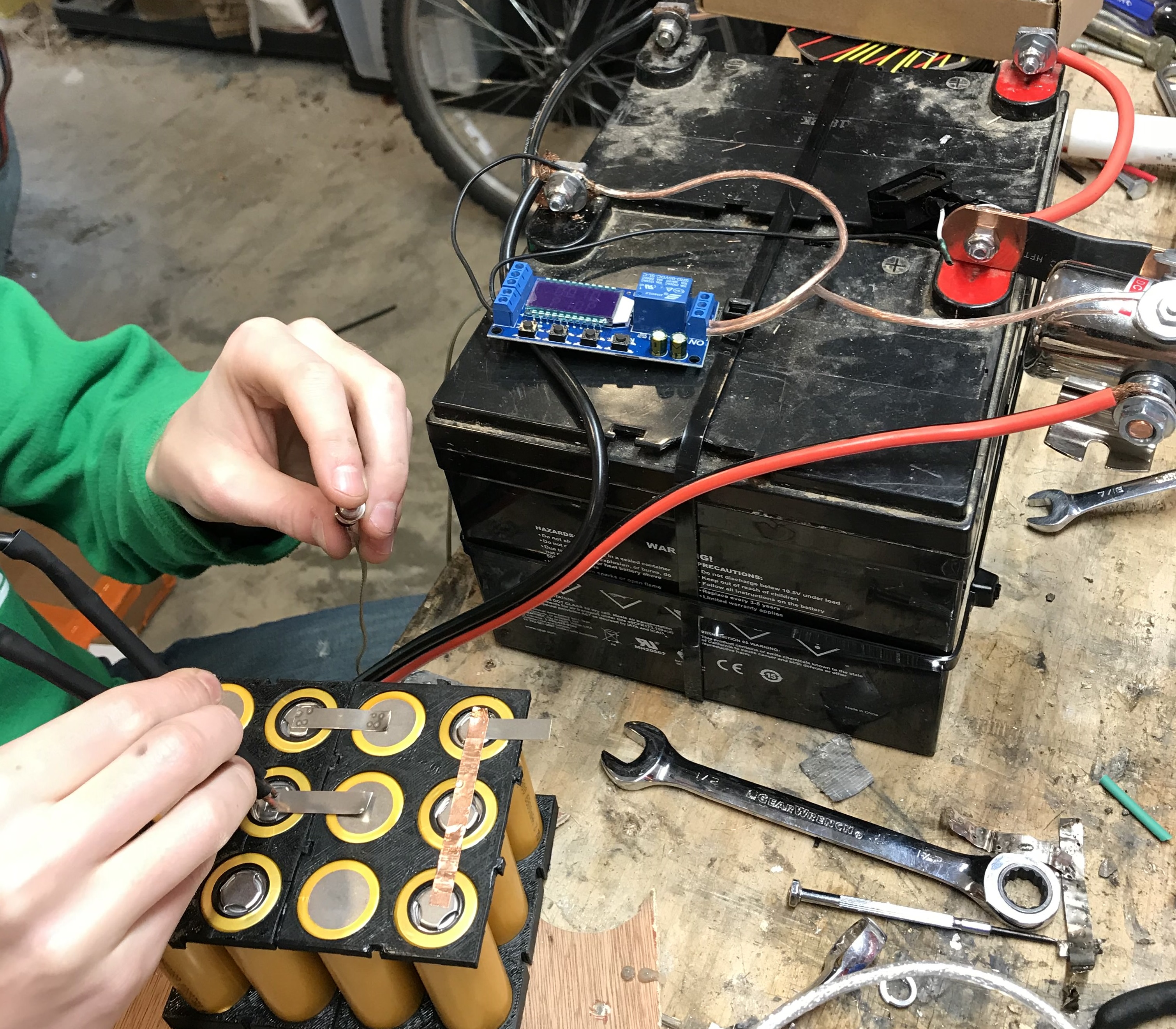

To safely connect cylindrical cell batteries into large packs (see right) one needs a spot welder to

weld nickel strips to connect the batteries. After buying one that didn't work, I decided to make my

own. Others should be able to use this as a guide.

Step 1: Do your research

I am sure you are here because you were shocked by the price of a spot welder and thought

"I can make that". I was inspired to do so after a comment on my reddit

post recommended a Youtube video. Whatever the reason

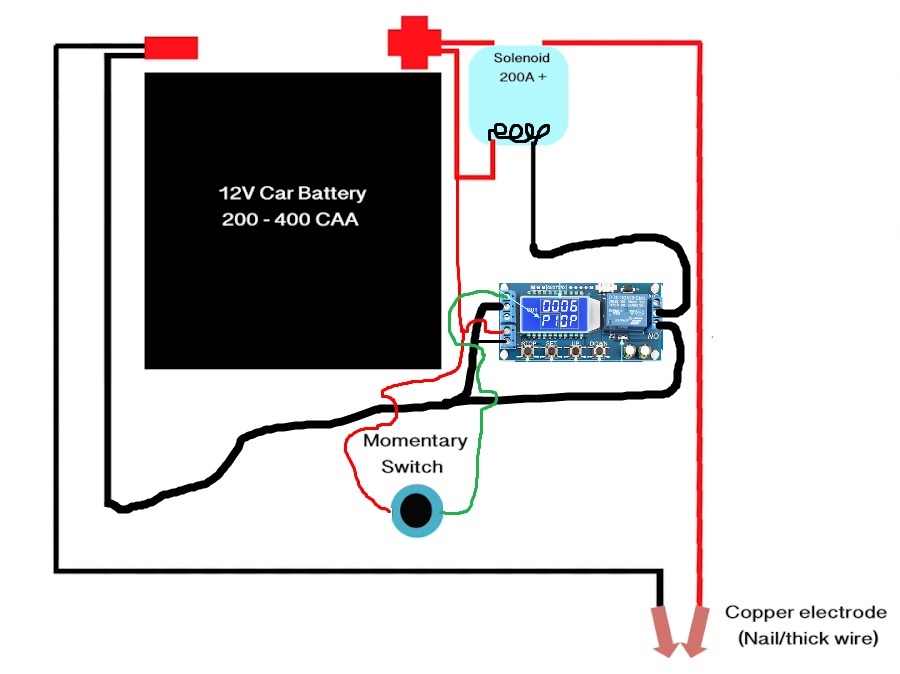

for your need, the basic premise is as follows: You use a car relay to short a 12 volt car battery,

sending hopefully hundreds of amps through your nickel strip. You should use some sort of timer to turn

the car relay on and off precisely. I bought a timer attached to a relay, but an arduino with a relay

would work great as well. (SRD-05VDC-SL-C is a good one, and the one embedded in my timer)

Step 2: Purchase the parts

Here's what you need:

** I originally used part of a copper bus bar and used some tin snips to shape it into a point. This did not work consistently. I ended up looting the electrodes from the previous failed spot welder purchase. I would either buy copper nails or purchase a pair of electrodes from Amazon. (That one is just an example, probably cheaper options out there.)

- Car Starter Relay

- Timer Relay*

- Copper Electrodes**

- Low Gauge Wire

- Push Button (any button will work, not a toggle switch though.)

- Car Battery (I don't have one to recommend, but just make sure to use a lead acid.)

** I originally used part of a copper bus bar and used some tin snips to shape it into a point. This did not work consistently. I ended up looting the electrodes from the previous failed spot welder purchase. I would either buy copper nails or purchase a pair of electrodes from Amazon. (That one is just an example, probably cheaper options out there.)

Step 3: Put it together already!

Go To Top Guess what? I made this website! Check it and many of my other projects on my github.